Last Updated on September 5, 2023 by Mark S. Taylor

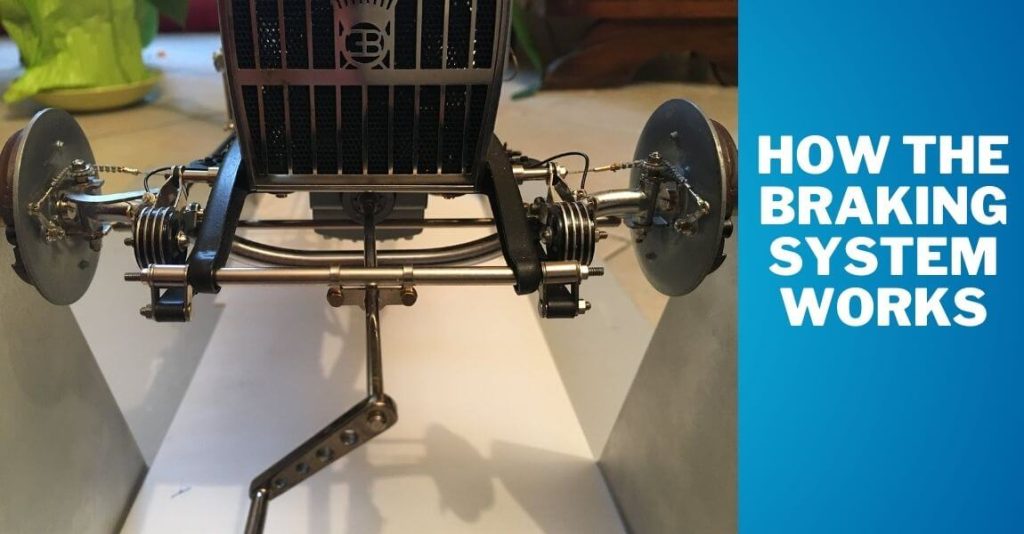

The braking system works by converting kinetic energy into thermal energy to slow down or stop a vehicle. When the driver presses the brake pedal, hydraulic pressure is applied to the brake pads, creating friction against the rotating brake discs or drums.

This friction causes the vehicle to decelerate as the kinetic energy is transferred into heat energy, which is then dissipated through the brake system. By effectively controlling the braking force, the system ensures the vehicle comes to a controlled stop, preventing accidents and ensuring passenger safety.

The braking system is a critical component of any vehicle, allowing drivers to maintain control and navigate safely on the roads.

Contents

Understanding The Basics

Learn the basics of how the braking system works in your vehicle. Discover how the key components come together to ensure safe and effective stopping power. Gain a deeper understanding of this essential part of your car’s functionality.

Introduction To The Braking System Components

The braking system is an essential component of any vehicle, ensuring safe and controlled deceleration. Understanding how it works can help you appreciate the complex mechanisms at play when you press the brake pedal. In this section, we will explore the different components of the braking system, starting with the master cylinder.

The Role Of The Master Cylinder In The Braking System

The master cylinder is a critical part of the braking system, responsible for converting the pressure applied to the brake pedal into hydraulic force. Here are some key points to understand about the master cylinder:

- Function: The master cylinder generates hydraulic pressure that is used to engage the brakes.

- Hydraulic System: It operates on the principle of hydraulics, utilizing a piston and a series of tubes filled with brake fluid.

- Brake Fluid Reservoir: The master cylinder contains a brake fluid reservoir, which supplies the fluid needed for the hydraulic system.

- Brake Pedal Connection: When you press the brake pedal, it activates the piston inside the master cylinder, exerting pressure on the brake fluid.

The master cylinder plays a crucial role in maintaining reliable braking performance, ensuring efficient operation of the entire braking system when you need to slow down or come to a complete stop.

Exploring The Brake Pedal And Its Connection To The Braking System

The brake pedal is the most visible component of the braking system, serving as the primary interface between the driver and the brakes. Let’s delve into some important aspects related to the brake pedal:

- Driver Input: When the driver presses the brake pedal, it triggers a series of actions that ultimately engage the brakes.

- Linkage Mechanism: The brake pedal is connected to the master cylinder through a linkage mechanism, which transfers the force exerted by your foot.

- Brake Light Activation: In addition to controlling the brakes, the brake pedal also activates the brake lights, signaling your intention to slow down or stop to other drivers on the road.

Understanding how the brake pedal functions in tandem with other brake system components is key to grasping the overall mechanics of a vehicle’s braking system.

By familiarizing yourself with the essential components of the braking system, such as the master cylinder and brake pedal, you gain insight into the inner workings of this critical safety mechanism. In the subsequent sections, we will explore additional components that work in harmony to slow down your vehicle efficiently.

So, let’s continue our journey in understanding the intricacies of the braking system together.

Hydraulic Brake System

A hydraulic brake system works by using fluid pressure to transfer force from the brake pedal to the brakes. When the pedal is pressed, the fluid is compressed, generating hydraulic pressure that activates the brakes. This system allows for efficient and reliable stopping power in vehicles.

How Hydraulic Brake Systems Work:

Hydraulic brake systems play a critical role in ensuring the safety and performance of vehicles. By converting the force exerted on the brake pedal into hydraulic pressure, these systems enable effective braking. Let’s delve into the inner workings of hydraulic brake systems and gain a better understanding of their components and functions.

Examining The Brake Fluid And Its Importance In The System:

The hydraulic brake system relies heavily on brake fluid to function properly. Here’s a closer look at the brake fluid and its significance within the system:

- Brake fluid acts as a medium for transmitting hydraulic pressure within the system.

- It plays a crucial role in transferring the force applied on the brake pedal to the braking components.

- Brake fluid operates effectively under high temperatures without boiling or freezing.

- It must maintain its stability and consistency to ensure efficient braking performance.

- Regular inspection and replacement of brake fluid are essential to maintain the system’s reliability and safety.

Understanding The Brake Lines And Their Function In The Hydraulic System:

To comprehend the hydraulic brake system fully, we need to understand the role of brake lines. These lines serve as essential conduits for transmitting brake fluid to the various braking components. Here’s what you need to know about brake lines:

- Brake lines are composed of durable steel or flexible rubber hoses.

- They connect the master cylinder to the brake calipers or wheel cylinders.

- When the brake pedal is pressed, brake fluid is forced through the brake lines.

- The brake lines ensure that hydraulic pressure is distributed evenly to all braking components.

- Regular inspection of brake lines is crucial to identify and address any signs of leakage or damage.

Hydraulic brake systems depend on the effective functioning of brake fluid and brake lines. Understanding these components and their roles will enable you to appreciate the intricate mechanisms responsible for your vehicle’s braking capabilities. Remember to maintain and inspect your brake fluid and brake lines regularly to ensure optimal performance and safety on the road.

Disc Brakes Vs Drum Brakes

Disc brakes and drum brakes are two types of braking systems used in vehicles. Disc brakes work by applying friction to the disc, while drum brakes use friction applied to the inside of a drum. Both systems play a crucial role in stopping the vehicle by converting kinetic energy into heat.

Differentiating Between Disc Brakes And Drum Brakes

Disc brakes and drum brakes are the two primary types of braking systems used in vehicles. While they both serve the same purpose of decelerating a moving vehicle, there are notable differences in their design and functionality. Understanding these differences can help you make an informed decision when it comes to choosing the right braking system for your vehicle.

Here are the key points of differentiation between disc brakes and drum brakes:

- Design: Disc brakes consist of a rotor, brake caliper, and brake pads, whereas drum brakes consist of a brake drum, wheel cylinder, brake shoes, and return springs.

- Friction Mechanism: In disc brakes, the brake pads clamp onto the rotor to create friction, which slows down the vehicle. In drum brakes, brake shoes expand outward against the brake drum, generating friction and causing the vehicle to slow down.

- Heat Dissipation: Disc brakes are known for their superior heat dissipation capabilities, as the rotor’s exposed design allows heat to dissipate quickly. On the other hand, drum brakes retain more heat due to their enclosed design, which can lead to decreased braking efficiency during prolonged use.

- Braking Performance: Disc brakes generally offer better overall braking performance, especially during sudden stops or emergency situations. They provide consistent and responsive braking power, allowing for shorter stopping distances. Drum brakes, while effective for everyday use, may exhibit brake fade during heavy or continuous braking.

- Maintenance: Disc brakes are relatively easier to maintain compared to drum brakes. Disc brake pads can be easily replaced when worn out, and the rotors can be resurfaced if necessary. In contrast, drum brakes require periodic adjustments to ensure optimal performance, and their components may need to be replaced as a set.

- Weight and Cost: Disc brakes are generally lighter and costlier than drum brakes. The added weight of drum brakes can impact fuel efficiency, especially in smaller vehicles. On the other hand, disc brakes tend to be more expensive when it comes to upfront costs and replacement parts.

Exploring The Advantages And Disadvantages Of Disc Brakes

Disc brakes have gained popularity in the automotive industry due to their numerous advantages, but they also have some limitations. It’s essential to weigh both the pros and cons to determine if disc brakes are the right choice for your vehicle.

Advantages of Disc Brakes:

- Efficient heat dissipation, preventing brake fade and maintaining consistent performance.

- Improved braking performance, offering shorter stopping distances and better responsiveness.

- Easier maintenance, with quick and straightforward replacement of brake pads and resurfacing of rotors.

- Enhanced safety, especially during sudden stops or emergency braking situations.

- Compatibility with antilock braking systems (ABS), allowing for better control and stability.

Disadvantages of Disc Brakes:

- Higher upfront costs compared to drum brakes.

- Vulnerable to water and debris, which can affect braking performance in extreme conditions.

- Limited ability to provide parking brake functionality, requiring an additional parking brake system.

Understanding The Benefits And Limitations Of Drum Brakes

While disc brakes have become more prevalent, drum brakes still have their place in certain vehicle applications. Understanding their benefits and limitations can help you determine if drum brakes are suitable for your specific needs.

Benefits of Drum Brakes:

- Cost-effective compared to disc brakes, making them a common choice for budget-friendly vehicles.

- Effective parking brake mechanism, eliminating the need for a separate system.

- Adequate braking performance for everyday driving scenarios.

- Good protection against water and debris due to their enclosed design.

Limitations of Drum Brakes:

- Less efficient heat dissipation, which can lead to reduced performance during prolonged use.

- Longer braking distances and less responsive braking compared to disc brakes.

- More intricate maintenance requirements, including periodic adjustments and potential replacement of multiple components.

By understanding the differences and weighing the advantages and disadvantages of disc brakes and drum brakes, you can make an informed decision based on your vehicle type, driving style, and desired performance. Whether you opt for the superior performance of disc brakes or the cost-effectiveness of drum brakes, ensuring the proper maintenance and regular inspection of your braking system is essential for your safety on the road.

Brake Pads And Shoes

Brake pads and shoes are essential components of a car’s braking system. They create friction with the rotors or drums to slow down and stop the vehicle, ensuring safe driving. Understanding how these parts work is crucial for maintaining optimal braking performance.

The importance of brake pads and shoes in the braking system:

Both brake pads and shoes play a crucial role in ensuring the safe operation of a vehicle’s braking system. They work by creating friction against the brake rotors or drums, which slows down or stops the vehicle. Here’s why they are so important:

- Brake pads and shoes are the primary components responsible for converting the kinetic energy of a moving vehicle into heat energy, effectively bringing the vehicle to a stop.

- They need to provide sufficient friction to allow for efficient braking without causing excessive wear on the brake rotors or drums.

Different types of brake pads and their characteristics:

- There are several types of brake pads available in the market, each with its own set of characteristics. Here’s an overview:

- Organic brake pads: Made from a mix of fibers, binding resins, and fillers, these pads offer good stopping power, low noise, and produce minimal brake dust. However, they can wear out faster and may not be suitable for high-performance vehicles.

- Ceramic brake pads: Composed of ceramic fibers, bonding agents, and fillers, these pads provide excellent braking performance, particularly at high temperatures. They are also quieter, produce less brake dust, and have a longer lifespan. However, they tend to be more expensive than other types.

- Semi-metallic brake pads: These pads contain a blend of metal fibers, friction modifiers, and fillers. They offer superior heat dissipation, making them suitable for heavy-duty use. While they provide excellent stopping power, they can be noisy and generate more brake dust.

Advantages and disadvantages of various brake pad materials:

- When it comes to brake pad materials, each has its own advantages and disadvantages. Here’s a breakdown:

- Organic brake pads:

- Advantages: Good stopping power, low noise, minimal brake dust production.

- Disadvantages: Faster wear, may not be suitable for high-performance vehicles.

- Ceramic brake pads:

- Advantages: Excellent braking performance, low noise, reduced brake dust, longer lifespan.

- Disadvantages: Higher cost compared to other options.

- Semi-metallic brake pads:

- Advantages: Superior heat dissipation, excellent stopping power.

- Disadvantages: Noise generation, increased brake dust.

Remember, your choice of brake pads should be based on factors such as driving habits, vehicle type, and budget. Regular inspections and maintenance will ensure optimal brake performance and your safety on the road.

Brake Calipers And Wheel Cylinders

Brake calipers and wheel cylinders are vital components of a car’s braking system. These components work together to apply pressure to the brake pads or shoes, allowing the vehicle to slow down and come to a stop efficiently and safely.

Examining The Role Of Brake Calipers In Disc Brake Systems

Brake calipers play a crucial role in the functioning of disc brake systems. Here’s a look at their main responsibilities:

- Applying the pressure: Whenever the driver presses the brake pedal, the brake fluid is sent through the master cylinder to the calipers. The calipers use this hydraulic pressure to press the brake pads against the rotor. This action creates friction and slows down the vehicle.

- Squeezing the brake pads: Calipers are responsible for housing the brake pads and keeping them properly aligned. Using pistons and brake pads, the calipers apply pressure evenly to the rotor surface, enabling efficient braking performance.

- Controlling the force: To ensure effective braking, calipers are designed with pistons that move in and out. This movement allows the brake pads to grip the rotor with the right amount of force. Brake calipers need to be sturdy and resistant to heat and corrosion to withstand the demands of braking.

Understanding The Function Of Wheel Cylinders In Drum Brake Systems

In drum brake systems, wheel cylinders take on the critical role of generating friction to slow down the vehicle. Here’s an overview of their function:

- Converting hydraulic pressure: Wheel cylinders convert hydraulic pressure from the brake system into mechanical force. When the driver presses the brake pedal, the brake fluid is directed into the wheel cylinders, causing them to expand.

- Pushing the brake shoes: As the wheel cylinders expand, they push the brake shoes outwards. This movement causes the brake shoes to make contact with the brake drum, generating friction that slows down the rotation of the wheels.

- Creating balanced braking: Wheel cylinders work in pairs, with one located on each end of the brake shoes. This symmetrical setup ensures that the brake shoes are pushed against the drum with equal force, promoting balanced braking and preventing uneven wear.

- Releasing the brakes: After the driver releases the brake pedal, the wheel cylinders retract the brake shoes. This action creates clearance between the shoes and the drum, allowing the wheels to rotate freely.

Exploring The Factors That Affect The Performance Of Calipers And Cylinders

Several factors can influence the performance of brake calipers and wheel cylinders. Understanding these factors is essential for maintaining optimal braking efficiency. Here’s what you need to know:

- Material quality: High-quality materials, such as stainless steel or aluminum, contribute to the durability and effectiveness of both calipers and cylinders. Weather-resistant coatings can also enhance their longevity.

- Heat dissipation: Calipers and cylinders must effectively dissipate heat to prevent brake fade and maintain consistent performance. Proper ventilation and heat-resistant materials can assist in this process.

- Proper lubrication: Caliper slide pins and cylinder pistons require appropriate lubrication to ensure smooth movement and prevent binding. Regular lubrication and inspection can help identify any issues early on.

- Regular maintenance: Calipers and wheel cylinders should be inspected and maintained regularly to detect any signs of wear or damage. This includes checking for leaking brake fluid, uneven pad wear, and any abnormal noises during braking.

- Correct installation: Proper installation of calipers and cylinder components is crucial for their optimal performance. Following manufacturer guidelines and torque specifications helps ensure their effectiveness.

By considering these factors and addressing any issues promptly, you can help maintain the performance and reliability of your brake calipers and wheel cylinders.

Remember, regular brake system inspections and appropriate maintenance are vital for your safety on the road.

Brake Rotors And Drums

The braking system relies on the effectiveness of brake rotors and drums to slow down or stop a vehicle. These components generate friction with the brake pads, converting the kinetic energy into heat energy, resulting in deceleration or halting the vehicle.

When it comes to understanding how the braking system works, it is essential to delve into the intricacies of brake rotors and drums. These two components play a crucial role in the braking process, ensuring your vehicle comes to a safe and controlled stop.

Let’s explore how brake rotors work in disc brake systems and understand the function of brake drums in drum brake systems. Additionally, we’ll compare the differences between rotors and drums to provide a comprehensive understanding of these vital braking system components.

How Brake Rotors Work In Disc Brake Systems:

- Brake rotors, also referred to as brake discs, are an essential part of disc brake systems.

- They are typically made of cast iron or carbon composite materials, providing durability and heat dissipation capabilities.

- The brake rotors are attached to the wheel hub and rotate along with the wheels.

- When you press the brake pedal, hydraulic pressure is applied to the brake caliper, which subsequently squeezes the brake pads against the brake rotors.

- The friction between the brake pads and the rotors creates the necessary resistance to slow down or bring the vehicle to a complete stop.

- The heat generated during this process is dissipated through venting or cooling vanes in the rotor’s design.

- The smooth and consistent rotor surface is crucial for proper braking performance, as any irregularities can lead to vibrations and decreased efficiency.

- Regular inspection and maintenance of the brake rotors are necessary to ensure their optimal functionality and safety on the road.

Understanding The Function Of Brake Drums In Drum Brake Systems:

- Brake drums, unlike brake rotors, are utilized in drum brake systems, commonly found in older vehicles and certain applications.

- A brake drum is a cylindrical-shaped component, typically made of cast iron, which is attached to the wheel hub.

- Inside the brake drum, there are brake shoes equipped with friction material that push against the drum’s inner surface when the brake pedal is applied.

- As the brake shoes make contact with the rotating drum, the friction generates resistance, thereby slowing down or stopping the vehicle.

- Drum brake systems rely on a series of springs, levers, and hydraulic components to activate and retract the brake shoes, providing the necessary braking force.

- Unlike disc brakes, brake drums are enclosed, which helps protect the braking system from external elements like water and debris.

- Proper maintenance of brake drums includes periodic adjustment of the brake shoes and inspection for any signs of wear or damage that may affect braking performance.

Comparing The Differences Between Rotors And Drums:

Brake rotors and drums differ significantly in their design, location, and function. Let’s explore the distinctions between these two crucial components:

- Rotors are utilized in disc brake systems, whereas drums are used in drum brake systems.

- Brake rotors are typically exposed, visible through the wheel, while brake drums are enclosed within the brake assembly.

- Rotors are attached to the wheel hub and rotate along with the wheels, while drums are also affixed to the wheel hub but do not rotate.

- Disc brake systems are known for their superior performance and heat dissipation capabilities, making them ideal for high-performance vehicles, whereas drum brake systems are generally used in lighter-duty vehicles.

- Brake rotors are typically more expensive to replace compared to brake drums.

- Disc brakes generally provide better stopping power and are more responsive, whereas drum brakes may require more time to engage and generate braking force.

- Brake rotors are less prone to brake fade, a condition where braking efficiency decreases due to excessive heat build-up, while drum brakes are more susceptible to this problem.

Brake rotors and drums are essential components of the braking system, each with unique characteristics and functions. While brake rotors are utilized in disc brake systems and offer superior performance, brake drums find their place in drum brake systems and are commonly found in older vehicles.

Understanding how these components work and their differences can help you make informed decisions about maintenance, repair, and future enhancements to your vehicle’s braking system.

Anti-Lock Braking System (Abs)

The Anti-lock Braking System (ABS) is a crucial component of a vehicle’s braking system. It prevents the wheels from locking up, ensuring better control and stability during braking. ABS works by rapidly pulsing the brakes to prevent skidding, allowing the driver to maintain steering control.

Explaining The Technology Behind The Anti-Lock Braking System

The anti-lock braking system, commonly known as ABS, is a vital component of modern vehicles. It is a safety feature that prevents wheel lock-up during braking, ensuring better control and traction. By understanding how ABS works, we can appreciate its role in enhancing road safety.

Here is a breakdown of the technology behind the anti-lock braking system:

- Sensors: ABS relies on sensors placed on each wheel to monitor their rotational speed. These sensors provide real-time feedback to the system, allowing it to detect any discrepancies in wheel rotation.

- Control Unit: The control unit serves as the brain of the ABS. It receives input from the sensors and processes the data to determine if and when wheel lock-up is imminent.

- Modulator Valves: The modulator valves are responsible for regulating the brake fluid pressure to prevent wheel lock-up. These valves pulsate the pressure to ensure that the wheels continue rotating, allowing the driver to maintain steering control.

- Electronic Control Unit (ECU): The ECU plays a crucial role in managing the ABS system. It continuously analyzes the sensor data and communicates with the modulator valves to adjust the brake fluid pressure accordingly.

- Hydraulic Pump: The hydraulic pump assists in maintaining the proper pressure for the braking system. When the ABS is activated, the pump increases or decreases the brake fluid pressure as needed.

Understanding How Abs Prevents Wheel Lock-Up During Braking

The primary purpose of ABS is to prevent the wheels from locking up when braking, ultimately enhancing vehicle control and stability. Here’s how the anti-lock braking system achieves this:

- Wheel Lock-up Detection: The ABS continuously monitors the rotational speed of each wheel. If one or more wheels slows down significantly compared to the others, indicating an impending lock-up, the system intervenes.

- Pressure Regulation: Upon detecting a potential wheel lock-up, the ABS modulator valves release pressure from the affected wheel(s) by rapidly pulsating the brake fluid pressure. This modulation allows the wheel(s) to continue rotating, preventing unwanted skidding.

- Steering Control: By preventing wheel lock-up, ABS ensures that the driver can maintain steering control even during emergency braking or slippery road conditions. This feature significantly improves maneuverability and reduces the risk of accidents.

Examining The Components And Sensors Used In Abs

The anti-lock braking system relies on various components and sensors to function effectively. Let’s take a closer look at them:

- Wheel Speed Sensors: These sensors, typically located at each wheel, measure the rotational speed. They provide essential data to the ABS system, enabling it to detect any deviations or anomalies.

- Control Unit: The ABS control unit processes the information received from the wheel speed sensors. It determines the appropriate response to prevent wheel lock-up and maintain optimal braking performance.

- Modulator Valves: Located within the brake lines, the modulator valves regulate brake fluid pressure to the individual wheels. This regulation ensures that the wheels do not lock up, allowing for controlled stopping even on slippery surfaces.

- Hydraulic Pump: The hydraulic pump works in conjunction with the modulator valves to adjust the brake fluid pressure as needed. It assists in preventing wheel lock-up while providing the necessary braking force.

- Electronic Control Unit (ECU): The ECU is responsible for coordinating the different components of the ABS system. It continuously analyzes the sensor data and communicates with the modulator valves and hydraulic pump to maintain optimal braking performance.

Understanding the technology behind the anti-lock braking system, how it prevents wheel lock-up, and the components involved helps us appreciate its importance in vehicle safety.

Brake Fluid And Maintenance

The brake fluid plays a crucial role in the functioning of the braking system, ensuring smooth and efficient stopping power. Regular maintenance is necessary to keep the brake fluid clean and at the recommended level for optimal performance.

Brake fluid is a crucial component of a vehicle’s braking system, as it plays a vital role in ensuring smooth and effective braking. Proper brake fluid maintenance is essential to ensure the optimal functioning of the braking system and to maintain safety on the road.

In this section, we will explore the importance of brake fluid maintenance, how to check and refill brake fluid, as well as potential signs of brake fluid contamination or degradation.

The Importance Of Brake Fluid Maintenance:

- Regular brake fluid maintenance is essential to ensure the safety and reliability of your vehicle’s braking system.

- Brake fluid tends to absorb moisture over time, which can lead to a decrease in its boiling point. This can affect the overall performance of your brakes, especially during prolonged or heavy braking.

- By regularly checking and maintaining the brake fluid, you can prevent moisture buildup and maintain the optimal boiling point, thus ensuring consistent braking performance.

Understanding How To Check And Refill Brake Fluid:

- To check the brake fluid level, locate the brake fluid reservoir, typically located near the master cylinder under the hood of your vehicle.

- Ensure that the vehicle is parked on a level surface and the engine is cool before opening the reservoir.

- Remove the cap of the reservoir and visually inspect the fluid level. It should be between the minimum and maximum levels indicated on the reservoir.

- If the fluid level is below the minimum mark, it is important to refill it with the recommended type of brake fluid specified in your vehicle’s owner’s manual.

- Use a clean funnel to carefully pour the brake fluid into the reservoir, ensuring that you do not overfill it.

- Securely replace the cap after refilling and make sure it is properly sealed.

Exploring The Signs Of Brake Fluid Contamination Or Degradation:

- Brake fluid can become contaminated or degraded over time due to moisture absorption, excessive heat, or prolonged use.

- Some signs of brake fluid contamination or degradation include a decrease in braking performance, a spongy or soft brake pedal feel, and a darker color of the brake fluid.

- If you notice any of these signs, it is essential to have your brake system inspected and the brake fluid flushed and replaced if necessary.

- Contaminated or degraded brake fluid can lead to the buildup of harmful deposits, corrosion of brake components, and a decrease in overall braking efficiency.

Remember, maintaining proper brake fluid levels and quality is crucial for the safety of your vehicle and everyone on the road. Regularly checking and refilling brake fluid, as well as addressing any signs of contamination or degradation, will help ensure the optimal performance of your vehicle’s braking system.

So, make it a priority to include brake fluid maintenance as part of your regular vehicle maintenance routine.

Brake System Troubleshooting

The braking system troubleshoots issues to ensure the proper functioning of the brakes. It is essential to understand how the braking system works for effective troubleshooting.

When it comes to the safety of your vehicle, a well-functioning braking system is essential. However, just like other components in your car, the brake system can encounter issues from time to time. Understanding common brake system problems, how to diagnose them, and what steps to take when experiencing brake system failures is crucial.

In this section, we will discuss some common brake system problems and their causes, provide tips for diagnosing brake system issues, and outline steps to take in case of brake system failures.

Common Brake System Problems And Their Causes:

- Spongy brakes: This occurs when the brake pedal feels soft or mushy, and it requires a longer distance to stop your vehicle. The possible causes include air in the brake lines, a brake fluid leak, or worn-out brake pads.

- Brake noise: If you notice squealing, grinding, or metallic noises when you apply the brakes, it typically indicates worn-out brake pads or shoes. Rotor or drum damage can also be a contributing factor.

- Brake fluid leak: Leaking brake fluid can lead to a decrease in brake performance or a complete loss of brakes. The leak may be caused by a damaged brake line, a faulty brake caliper, or a blown brake hose.

- Brake pedal pulsation: Pulsating or vibrating brake pedal can be a sign of warped brake rotors. Over time, excessive heat from braking can cause the rotors to warp, resulting in an uneven brake surface.

- ABS (Anti-lock Braking System) warning light: If the ABS warning light illuminates on your dashboard, it could indicate a problem with the ABS system. This may be caused by a faulty ABS sensor, a failed ABS module, or a malfunctioning brake fluid pump.

Tips For Diagnosing Brake System Issues:

- Listen carefully: Pay attention to any unusual sounds when applying the brakes. Squealing, grinding, or metallic noises may indicate worn-out brake pads or damaged rotors.

- Feel the brake pedal: If the brake pedal feels soft, spongy, or pulsates when you apply pressure, it may indicate air in the brake lines, a brake fluid leak, or warped rotors.

- Check the brake fluid level: Low brake fluid can affect brake performance. Check the brake fluid reservoir and ensure it is at the recommended level.

- Inspect the brake pads: Visually inspect the brake pads through the wheel spokes. If the pads appear extremely worn or unevenly worn, they may need replacement.

- Look for leaks: Inspect the brake lines, calipers, and hoses for any signs of leaks. Moisture or fluid around these components may indicate a leak.

Steps To Take When Experiencing Brake System Failures:

- Stay calm and focus: If you experience a brake system failure while driving, it is crucial to remain calm and focused. Panic can lead to poor decision making.

- Downshift and use the emergency brake: If your brakes fail, downshifting can help slow down the vehicle. Additionally, engage the emergency brake gradually to further reduce the speed.

- Look for a safe location to stop: Scan the road for a safe place to stop your vehicle. Try to avoid intersections, steep hills, or any busy areas.

- Use signals and horn: Alert other drivers by using your signals, hazard lights, and horn to indicate your intentions when stopping.

- Call for assistance: Once you have safely stopped, contact a professional mechanic or roadside assistance for help. They can provide the necessary repairs or towing services.

Remember, regular maintenance and inspections are essential to keep your braking system in good condition. If you encounter any brake system issues, it is advisable to consult a professional for an accurate diagnosis and appropriate repairs.

Upgrading And Modifying Brake Systems

The braking system in vehicles is responsible for ensuring safe stops and controlling speed. Upgrading and modifying brake systems can enhance performance, responsiveness, and overall safety on the road. Discover how these systems work to maintain control and optimize braking efficiency.

The braking system is a crucial component of any vehicle, ensuring optimal safety and control while on the road. While stock braking systems are designed to meet minimum safety requirements, some drivers may choose to upgrade and modify their brake systems to enhance performance and overall driving experience.

However, there are several factors to consider before making any modifications to your brake system. In this section, we will explore these factors, the benefits of performance brake upgrades, and the legal and safety implications of brake modifications.

Factors To Consider When Upgrading Brake Systems

When considering upgrading your brake system, it is important to take into account various factors that can influence the performance and functionality of your newly modified brakes. These factors include:

- Vehicle type and weight distribution: The type and weight distribution of your vehicle play a significant role in determining the appropriate brake upgrade. Heavier vehicles may require stronger brakes to ensure effective stopping power.

- Driving habits and conditions: Your driving habits and the typical conditions you encounter on the road also come into play. Aggressive drivers or those who frequently drive in demanding conditions may benefit from upgrades that offer increased heat dissipation and improved brake modulation.

- Budget: Modifying a brake system can be a significant investment. It is essential to establish a budget and determine the level of performance upgrade you are willing to pursue.

Exploring Performance Brake Upgrades And Their Benefits

Performance brake upgrades can offer several advantages compared to stock brake systems. These benefits include:

- Increased stopping power: Performance brake upgrades often provide enhanced stopping power, allowing for quicker and more efficient deceleration.

- Improved heat dissipation: Performance brakes are designed to better dissipate heat generated during braking, reducing the risk of brake fade.

- Enhanced brake modulation: Upgraded brake systems can offer improved brake modulation, allowing for better control and precision during braking maneuvers.

- Reduced brake rotor wear: Performance brake systems are often designed to be more efficient, resulting in reduced wear on brake rotors and pads, potentially lowering long-term maintenance costs.

Understanding The Legal And Safety Implications Of Brake Modifications

While upgrading and modifying brake systems may seem like a tempting option, it is essential to understand the legal and safety implications involved. Here are a few points to consider:

- Local regulations: Before making any modifications, it is crucial to familiarize yourself with the local regulations regarding brake system modifications. Some jurisdictions may have restrictions or specific requirements that must be met.

- OEM guidelines: Deviating from the original equipment manufacturer’s (OEM) specifications may have legal implications, especially if modifications compromise safety standards or vehicle warranty.

- Proper installation and compatibility: Performance brake upgrades should be installed by qualified professionals who understand the specific requirements and compatibility of the components being added or replaced.

- Testing and fine-tuning: After modifications are made, it is important to thoroughly test and fine-tune the new brake system to ensure its optimal performance and safety.

Before embarking on any brake system modification journey, it is advisable to consult with experts in the field to ensure that the upgrades are appropriate for your vehicle and comply with legal and safety requirements. By considering these factors, you can make informed decisions regarding your brake system upgrades while prioritizing safety and performance.

Frequently Asked Questions For How The Braking System Works

How Brake System Works Step By Step?

The brake system works by applying pressure to the brake pedal, which activates the brake fluid. The fluid then moves to the brake calipers, which squeeze the brake pads against the rotors. This friction slows down and stops the vehicle.

How Is A Brake System Of A Car Activated?

The brake system of a car is activated when the driver presses the brake pedal.

What Are The 3 Brake Systems?

The three brake systems are hydraulic, mechanical, and regenerative. Hydraulic brakes use fluid pressure, mechanical brakes use friction, and regenerative brakes use energy from deceleration.

How Does The Braking System Work?

The braking system in a vehicle converts kinetic energy to heat by applying friction to slow down or stop the vehicle. When the driver presses the brake pedal, hydraulic pressure is created, which then forces brake fluid to the wheels.

This pressure activates the brake pads or shoes, which make contact with the brake discs or drums, creating the necessary friction to slow down the vehicle.

Conclusion

Overall, understanding how the braking system works is essential for every driver. From the brake pedal to the wheels, each component plays a crucial role in ensuring safe and efficient braking. By pressing the brake pedal, hydraulic pressure is created, and this pressure is then transferred to the brake calipers or wheel cylinders, which force the brake pads or shoes to make contact with the brake discs or drums, ultimately slowing down or stopping the vehicle.

Regular maintenance and inspection of the braking system are vital to ensure its optimal performance and safety. Remember, the braking system is a complex yet essential mechanism that should never be taken for granted. By having a clear understanding of its functionality, you can drive with peace of mind, knowing that you have full control over the stopping power of your vehicle.

Stay safe on the road and always prioritize the maintenance of your braking system.